Dahaarka PVD

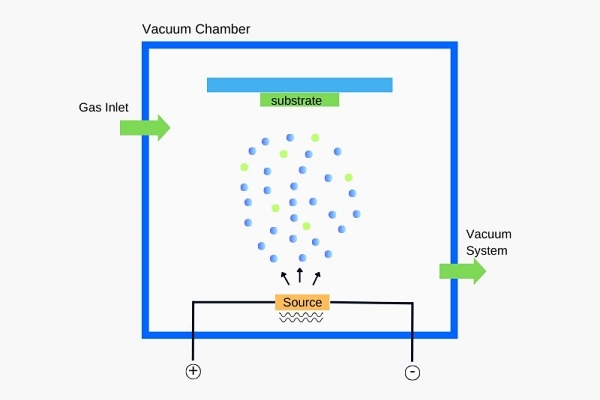

Tignoolajiyada PVD (Habka uumiga Jirka) waxaa loola jeedaa tignoolajiyada adeegsata hababka jireed ee xaaladaha faakuumka si ay u uumi ilaha walxaha gaasaska ama molecules, ama qayb ka mid ah iyaga oo gelinaya ion, oo dhiga filim khafiif ah oo leh hawlo gaar ah oogada dushiisa. .

Tiknoolajiyada PVD waa tignoolajiyada daaweynta dusha sare ee si weyn loogu isticmaalo wax ka beddelka dusha sare, shaqeynta, qurxinta, iwm. ee agabyada warshadaha kala duwan.

Hababka ugu muhiimsan ee dhigista uumiga jirka waxaa ka mid ah:

›Uumi-baxa

›Dahaarka kufidda

›dahaarka Arc balaasmaha

›dahaarka Ion

Waxaan bixinaaUumiga kulaylkaiyoUumi-baxa korantadawaxyaabaha laxidhiidha, oo ay ku jiraan xadhkaha laydhka elektarooniga ah, fiilooyinka uumiga tungsten, filaha tungsten qoriga elektarooniga ah, doomaha, agabka uumiga, iwm.

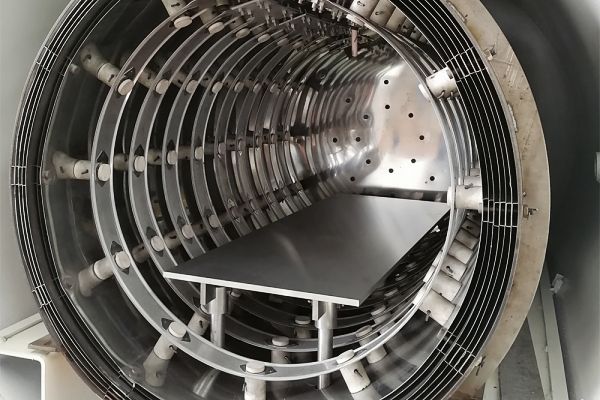

Foornada Vacuum

Foornooyinka faakuumka waxaa inta badan loo isticmaalaa toogashada dhoobada, dhalaalidda faakuumka, nadiifinta qaybaha faakuumka korantada, soo saarista, qaybo bir ah oo bir ah, xidhidh-xidhid dhoobo-bir ah, kaydinta uumiga jirka (PVD), iwm.

Waxaan bixinaa walxaha kuleyliyaha, doonyaha iyo sidayaal, gaashaaman kulaylka, xadhkaha goos gooska ah, fiilooyinka tungsten, iyo ilaha uumiga, qaybaha la warshadeeyay, xirmooyinka, iwm. Qalabka waa tungsten, molybdenum, ama tantalum, kuwaas oo la beddeli karo.

Photovoltaic & Semiconductor

Foornada kobaca silikoon hal-crystal ah, oo sidoo kale loo yaqaan foornada koritaanka silikoon ama foornada silikoon ingot, waa qalab gaar ah oo loo isticmaalo warshadaha sawir-qaadista iyo kuwa semiconductor si loo soo saaro silikoon hal-crystal tayo sare leh.

Silicon Monocrystalline waa sheyga aasaasiga ah ee soo saarida aaladaha semiconductor sida wareegyada isku dhafan (ICs), unugyada qorraxda, iyo dareemayaasha.

"Habka Czochralski" ayaa hadda ah habka ugu badan ee loo isticmaalo diyaarinta silikoon hal-crystal ah.

Waxaan bixinaa ulaha abuur molybdenum, tungsten iyo molybdenum liners crucible, xirayaasha, molybdenum qabsatooyinkooda, dubbayaasha carbide tungsten, iwm.

Muraayadaha Iyo Dhulka Naadirka ah

›Warshadaha dhalooyinka

Waxaan bixinaa electrodes molybdenum dhalidda dhalada.

Electrodes-kayada molybdenum-ka waxay ka samaysan yihiin 99.95% ulaha molybdenum-ka saafiga ah.

Cabbirka korantada Molybdenum: φ20-152 * L (cutub: mm), waxaan ku siin karnaa dusha alkali-dhaqmay, dusha makaanikada ah, iwm.

›Warshadaha Dhulka naadir

Warshadaha dhifka ah ee dhulka waxa ay ku lug leeyihiin soo saarista, habaynta, iyo ka faa’iidaysiga curiyayaasha dhulka naadirka ah, kuwaas oo ah qaybo muhiim ah oo ka mid ah tignoolajiyada horumarsan ee kala duwan iyo codsiyada.

Waxaan bixin karnaa tungsten, molybdenum, iyo walxaha kuleyliyaha tantalum, tungsten sintered, molybdenum crucibles, graphite crucibles, iwm.

Qalabka & Qalabka mitirka

›Diaphragm birta: Inta badan loo isticmaalo cabirrada cadaadiska diaphragm iyo gudbiyeyaasha. Agabka aan soo saarno waxaa ka mid ah SS316L, tantalum, titanium, HC276, Monel400, iyo Inconel625.

› Korodhka isha: Inta badan loo isticmaalo mitirada socodka korantada. Cabbirka korantada waa M3 ~ M8, agabkuna waxaa ka mid ah SS316L, tantalum, titanium, iyo HC276.

› Korodhka dhulka (giraanta dhulka):Inta badan waxaa loo istcimaalaa mitirada korantada, oo inta badan loo isticmaalo labo-labo. Cabirku wuxuu u dhexeeyaa DN25 ilaa DN600, agabka waxaa ka mid ah SS316L, tantalum, titanium, iyo HC276.

›Shaabadda diaphragm: loo isticmaalo in lagu go'doomiyo curiyaha cabbiraadda dhexdhexaadka ah. Qalabka diaphragm ee aanu soo saarno waxaa ka mid ah SS316L, titanium, HC276, iyo tantalum. ASME B 16.5, DIN EN 1092-1, iyo heerar kale oo la heli karo.

› Faraantiga dareeraya:loo isticmaalo shaabadaha diaphragm-ku-xidhan ee flange-ga, kaas oo ka saari kara wasakhda diaphragm-ka iyadoo la nadiifinayo oo nadiifinayo.

› Tuubbada ilaalinta heerkulbeegga:loo isticmaalo in lagu ilaaliyo thermocouples si caadi ah loogu isticmaalo codsiyada warshadaha kala duwan. Waxaan ku siinnaa tuubooyinka ilaalinta alaabta soo socota: tungsten, molybdenum, iyo tantalum.

Fadlan nala tasho ama ka eeg boggayaga si aad u hesho faahfaahin dheeraad ah iyo alaabooyin.

Nala Soo Xidhiidh

Amanda│Maareeyaha Iibka

E-mail: amanda@winnersmetals.com

Telefoon: +86 156 1977 8518 (WhatsApp/Wechat)

Haddii aad jeclaan lahayd inaad ogaato faahfaahin dheeraad ah iyo qiimaha alaabtayada, ha ka cabsan inaad la xiriirto maamulaha iibka (Amanda), waxay kuugu jawaabi doontaa sida ugu dhakhsaha badan (sida caadiga ah wax ka badan 12 saacadood), mahadsanid .